I-CALB engakwazi ukuhamba

I-CALB ayinyakazi ngenxa yokukhangisa ngokomzimba ku-resin ene-hydrophobic ephezulu eyi-macroporous, styrene/methacrylate polymer.I-Immobilized CALB ilungele ukusetshenziswa kuzincibilikisi zemvelo kanye nezinhlelo ezingenazo izincibilikisi, futhi ingagaywa kabusha futhi isetshenziswe kabusha izikhathi eziningi ezimeni ezifanele.

Ikhodi Yomkhiqizo: SZ-CALB- IMMO100A, SZ-CALB- IMMO100B.

★Umsebenzi ophezulu, ukukhetha okuphezulu kwe-chiral nokuzinza okuphezulu.

★Ukusebenza okungcono ezigabeni ezingenamanzi.

★Susa kalula ohlelweni lokusabela, nqamula ukusabela ngokushesha, futhi ugweme insalela yamaprotheni emkhiqizweni.

★Ingasetshenziswa kabusha futhi isetshenziswe kabusha ukuze kwehliswe izindleko.

| Umsebenzi | ≥10000PLU/g |

| Ibanga le-pH lokusabela | 5-9 |

| Ibanga lokushisa lokusabela | 10-60 ℃ |

| Ukubukeka | I-CALB-IMMO100-A: Okuphuzi okukhanyayo kuya kokuqinile okunsundu I-CALB-IMMO100-B: Okuqinile okumhlophe kuya kokunsundu ngokukhanyayo |

| Usayizi wezinhlayiya | 300-500μm |

| Ukulahlekelwa ekumisweni ku-105 ℃ | 0.5%-3.0% |

| I-resin ye-immobilization | I-Macroporous, i-styrene/methacrylate polymer |

| I-solvent yokusabela | Amanzi, i-organic solvent, njll., noma ngaphandle kwe-solvent.Ngokusabela kwezinye izinyibilikisi eziphilayo, amanzi angu-3% anganezelwa ukuthuthukisa umphumela wokusabela |

| Usayizi wezinhlayiya | I-CALB-IMMO100-A: 200-800 μm I-CALB-IMMO100-B: 400-1200 μm |

Incazelo yeyunithi: Iyunithi engu-1 ihambisana nokuhlanganiswa kwe-1μmol ngomzuzu we-propyl laurate kusuka ku-lauric acid ne-1-propanol ku-60℃.I-CALB-IMMP100-A engenhla ne-CALB-IMMO100-B ihambisana nabathwali abangakwazi ukuhamba abanosayizi abahlukene bezinhlayiyana.

1. Uhlobo lwe-reactor

I-enzyme enganyakazi iyasebenza kukho kokubili i-kettle batch reactor kanye ne-fixed bed continuous flow reactor.Kumele kuqashelwe ukugwema ukuchotshozwa ngenxa yamandla angaphandle ngesikhathi sokudla noma ukugcwalisa.

2. I-pH yokusabela, izinga lokushisa kanye ne-solvent

I-enzyme enganyakazi kufanele yengezwe ekugcineni, ngemuva kokuthi ezinye izinto zengezwe futhi zihlakazwe, futhi i-pH ilungiswe.

Uma ukusetshenziswa kwe-substrate noma ukwakhiwa komkhiqizo kuzoholela ekushintsheni kwe-pH ngesikhathi sokusabela, isigcinalwazi esanele kufanele sengezwe ohlelweni lokusabela, noma i-pH kufanele iqashwe futhi ilungiswe ngesikhathi sokusabela.

Ngaphakathi kwebanga lokubekezelela izinga lokushisa le-CALB (ngaphansi kuka-60 ℃), izinga lokuguqulwa liyenyuka ngokunyuka kwezinga lokushisa.Ekusetshenzisweni okungokoqobo, izinga lokushisa lokusabela kufanele likhethwe ngokuvumelana nokuzinza kwe-substrate noma umkhiqizo.

Ngokuvamile, ukusabela kwe-ester hydrolysis kufanelekile ohlelweni lwesigaba esinamanzi, kuyilapho ukusabela kwe-ester synthesis kufanelekile ohlelweni lwesigaba sezinto eziphilayo.I-solvent ephilayo ingaba i-ethanol, i-tetrahydrofuran, i-n-hexane, i-n-heptane ne-toluene, noma i-solvent ehlanganisiwe efanelekile.Ngokusabela kwezinye izinyibilikisi eziphilayo, amanzi angu-3% anganezelwa ukuthuthukisa umphumela wokusabela.

3. Ukusetshenziswa kabusha nempilo yesevisi ye-CALB

Ngaphansi kwesimo sokusabela esifanele, i-CALB ingatholwa futhi iphinde isetshenziswe, futhi izikhathi zohlelo lokusebenza ziyahlukahluka ngamaphrojekthi ahlukene.

Uma i-CALB etholiwe ingaphinde isetshenziswe ngokuqhubekayo futhi idinga ukugcinwa ngemva kokululama, idinga ukuwashwa futhi yomiswe futhi ivalwe ku-2-8 ℃.

Ngemuva kwemizuliswano embalwa yokusetshenziswa kabusha, uma ukusebenza kahle kokusabela kwehliswa kancane, i-CALB ingangezwa ngokufanelekile futhi iqhubeke nokusebenzisa.Uma ukusebenza kahle kokusabela kuncipha kakhulu, kudinga ukushintshwa.

Isibonelo 1(Aminolysis)(1):

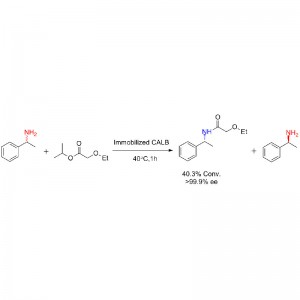

Isibonelo 2(Aminolysis)(2):

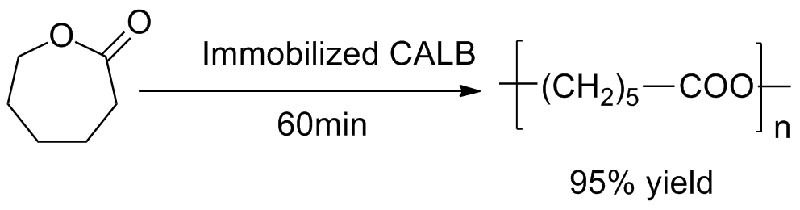

Isibonelo 3(I-polyester yokuvula indandatho)(3):

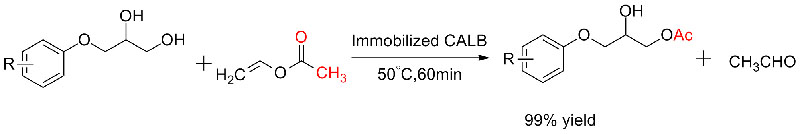

Isibonelo 4(I-Transesterification, i-regioselective yeqembu le-hydroxyl)(4):

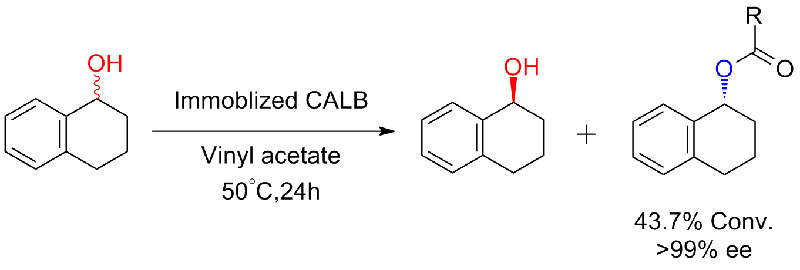

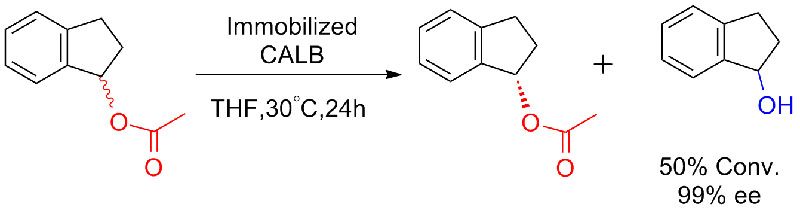

Isibonelo sesi-5(Transesterification, ukulungiswa kwe-kinetic kotshwala be-racemic)(5):

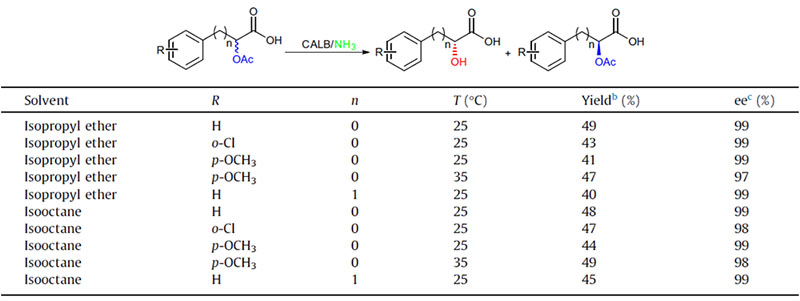

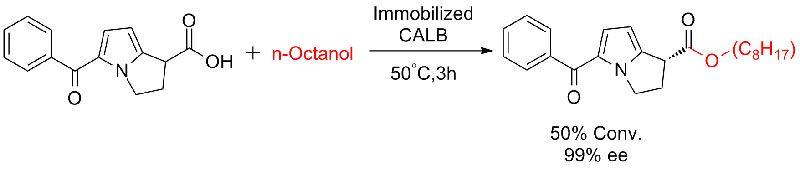

Isibonelo 6(I-Esterification, ukulungiswa kwe-kinetic ye-carboxylic acid)(6):

Isibonelo 7(I-Esterolysis, ukulungiswa kwe-kinetic)(7):

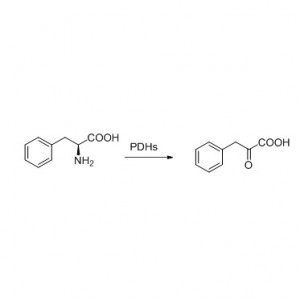

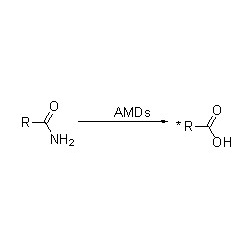

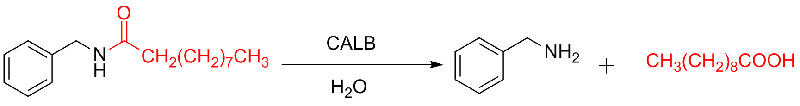

Isibonelo 8(I-Hydrolysis of amides)(8):

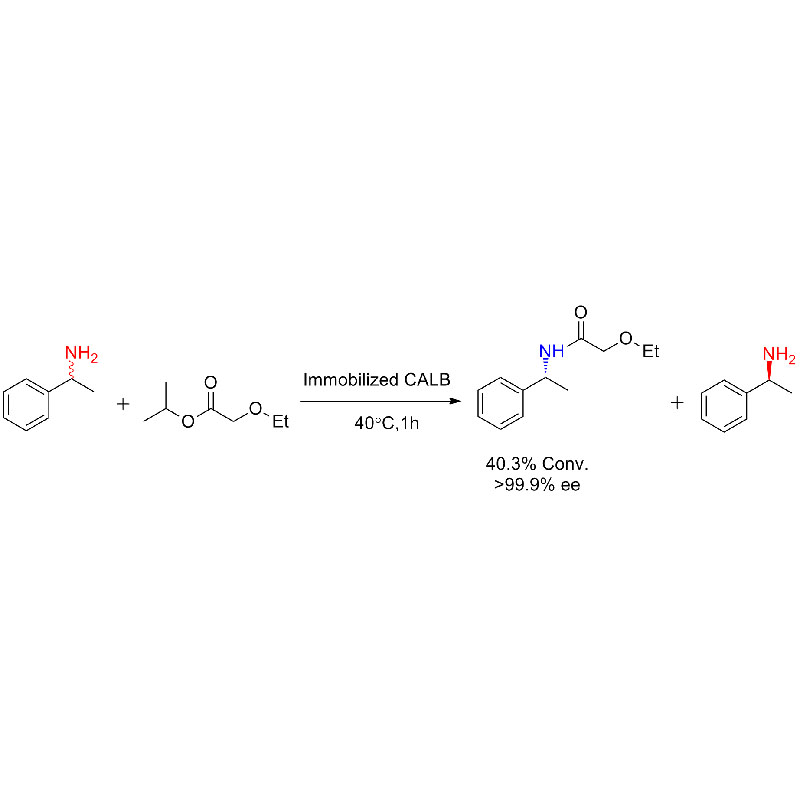

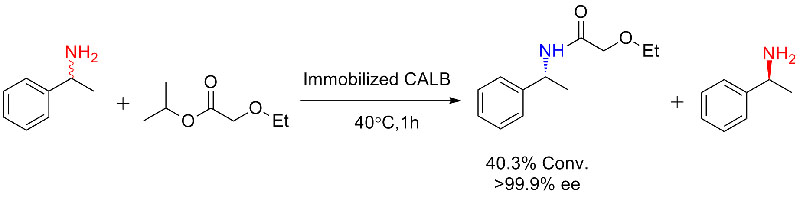

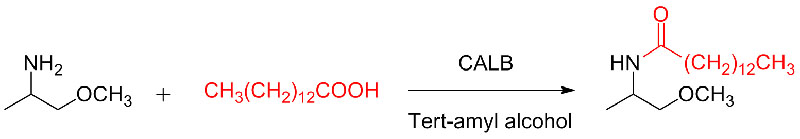

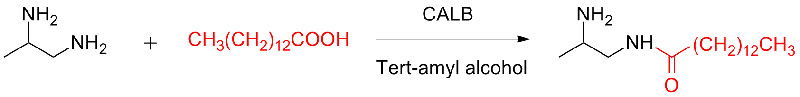

Isibonelo 9(Acylation of amines)(9):

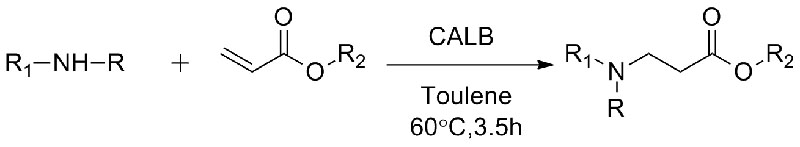

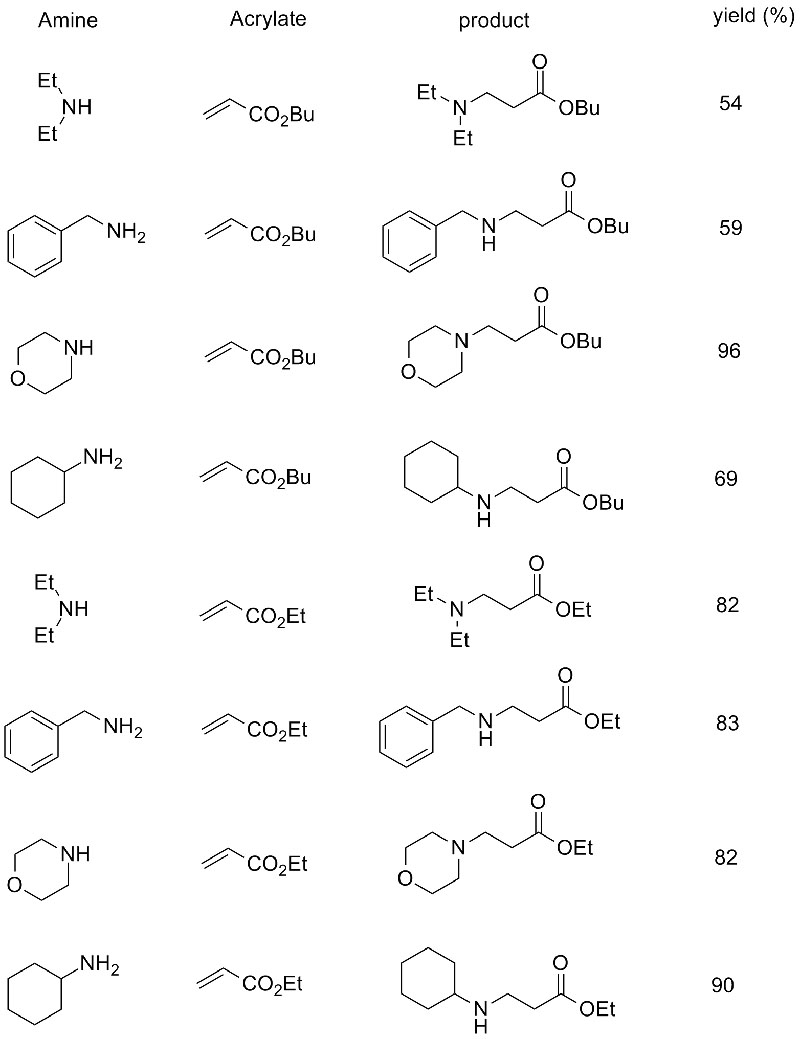

Isibonelo 10(Aza-Michael add reaction)(10):

1. Chen S, Liu F, Zhang K, e tal.I-Tetrahedron Lett, 2016, 57: 5312-5314.

2. Olah M, Boros Z, anszky GH, e tal.I-Tetrahedron, 2016, 72: 7249-7255.

3. Nakaoki1 T, Mei Y, Miller LM, e tal.I-Ind. Biotechnol, 2005, 1(2):126-134.

4. Pawar SV, Yadav G DJ Ind. Eng.Chem, 2015, 31: 335-342.

5. I-MP yase-Kamble, i-Shinde SD, i-Yadav G DJ Mol.I-Catal.B: I-Enzym, 2016, 132: 61-66.

6. Shinde SD, Yadav G D. Inqubo ye-Biochem, 2015, 50: 230-236.

7. Souza TC, Fonseca TS, Costa JA, e tal.J. Mol.I-Catal.B: I-Enzym, 2016, 130: 58-69.

8. Gavil'an AT, Castillo E, Lopez-Mungu'AJ Mol.I-Catal.B: I-Enzym, 2006, 41: 136-140.

9. Joubioux FL, Henda YB, Bridiau N, e tal.J. Mol.I-Catal.B: I-Enzym, 2013, 85-86: 193-199.

10. Dhake KP, Tambade PJ, Singhal RS, e tal.I-Tetrahedron Lett, 2010, 51: 4455-4458.